The Tablet & Capsule Elevator is designed to eliminate the need for manual feeding of tablets / capsules from the floor mounted hopper to the hopper of blister packing, counting or similar machines at a higher level. The machine complies with cGMP and safety regulations. All product contact parts are made of SS 316L and can be dismantled easily, without the use of any tool.

Special Features

- CE certified design with all electrical safety compliances.

- Product hopper capacity 100 litres. Higher capacity available on demand.

- Easy to use; easily operable by unskilled worker.

- Pneumatic scoop lift.

- Vibratory feeder with suitable dust extraction points.

- Single scoop of 4 to 6 litres with auto level detection

- Gentle lifting and tilting of scoop eliminates damage of delicate products.

- Fully enclosed from all sides with transparent polycarbonate guards.

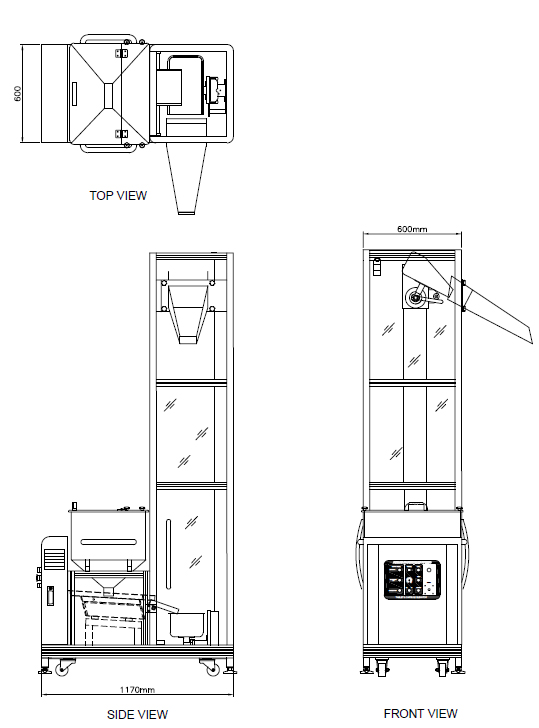

- Standard tilting height of 2000 mm, other heights are available as per customer requirement.

- Additional sensor provided for packing machine hopper's level detection and synchronization.

- Required product level in the hopper of the packing machine maintained all the time.

- Height adjustable discharge chute

- Double product feeding speed.

- Feed capacity of 280 to 300 kg/hr.

- High speed model product feeding discharge speed is 540 Ltr - 810 Ltr per hour.

- Dual feeding discharge.